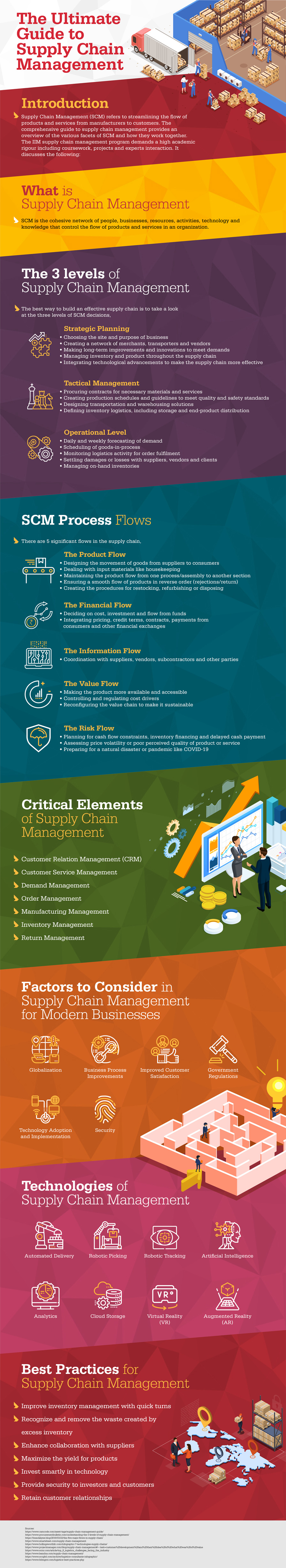

Globalization has become an undeniable part of e-commerce over the last few decades. Supply chains have had to ensure optimal efficiency and cost-effectiveness as they pass through numerous countries to obtain goods. Managing a supply chain requires a dedicated team in every area the chain touches. It’s obvious to say that supply chain management is both an art and a science. Specialization in supply chain management is the need of the hour for professionals to understand the supply chain, logistics, and processes involved in the businesses. The IIM Supply Chain Management program of IIM Udaipur is the only one-year MBA that offers an intensive specialization in supply chain management. The infographic listed below highlights various aspects of supply chain management. Let’s get started.

Introduction

Supply Chain Management (SCM) refers to streamlining the flow of products and services from manufacturers to customers. The comprehensive guide to supply chain management provides an overview of the various facets of SCM and how they work together. The IIM supply chain management program demands a high academic rigour including coursework, projects and experts interaction. It discusses the following:

What is Supply Chain Management?

SCM is the cohesive network of people, businesses, resources, activities, technology and knowledge that control the flow of products and services in an organization.

The 3 levels of Supply Chain Management

The best way to build an effective supply chain is to take a look at the three levels of SCM decisions:

Strategic Planning

- Choosing the site and purpose of business

- Creating a network of merchants, transporters and vendors

- Making long-term improvements and innovations to meet demands

- Managing inventory and product throughout the supply chain

- Integrating technological advancements to make the supply chain more effective

Tactical Management

- Procuring contracts for necessary materials and services

- Creating production schedules and guidelines to meet quality and safety standards

- Designing transportation and warehousing solutions

- Defining inventory logistics, including storage and end-product distribution

Operational Level

- Daily and weekly forecasting of demand

- Scheduling of goods-in-process

- Monitoring logistics activity for order fulfilment

- Settling damages or losses with suppliers, vendors and clients

- Managing on-hand inventories

SCM process flows

There are 5 significant flows in the supply chain.

The Product Flow

- Designing the movement of goods from suppliers to consumers

- Dealing with input materials like housekeeping

- Maintaining the product flow from one process/assembly to another section

- Ensuring a smooth flow of products in reverse order (rejections/return)

- Creating the procedures for restocking, refurbishing or disposing

The Financial Flow

- Deciding on cost, investment and flow from funds

- Integrating pricing, credit terms, contracts, payments from consumers and other financial exchanges

The Information Flow

- Coordination with suppliers, vendors, subcontractors and other parties

The Value Flow

- Making the product more available and accessible

- Controlling and regulating cost drivers

- Reconfiguring the value chain to make it sustainable /li>

The Risk Flow

- Planning for cash flow constraints, inventory financing and delayed cash payment

- Assessing price Volatility or poor perceived quality of product or service

- Preparing for a natural disaster or pandemic like COVID-19

Critical Elements of Supply Chain Management

- Customer Relation Management (CRM)

- Customer Service Management

- Demand Management

- Order Management

- Manufacturing Management

- Inventory Management

- Return Management

Strategy for interaction with current and potential customers

Communication between customers and the company

Demand forecast for products/services

Process of point-of-sale interest in delivering the product/service to customers

Process of planning, scheduling and supporting the manufacturing process

Process of organizing raw materials as well as finished products.

Faster and more comfortable return process

Supply Chain Management Challenges for Modern Businesses

- Globalization

- Business Process Improvements

- Improved Customer Satisfaction

- Government Regulations

- Technology Adoption and Implementation

- Security

Globalization leads companies to outsource manufacturing operations to several countries which complicates the supply chain

Adopting and onboarding new advances in business processes can be overwhelming

64% of customers don’t want to pay anything extra for less than two-day shipping

Carriers face regulatory compliances imposed by union, state and local authorities

From simplifying supply chain processes to enhancing efficiency, technology implementation should always be a benefit

Security vulnerabilities are an ever-more prominent threat

Supply Chain Management Technologies

- Automated Delivery use robots and other autonomous vehicles to increase efficiency

- Robotic Picking allows the supply chain to cut costs, eliminate errors, speed up processes and link applications

- Robotic Tracking use RFID (Radio-Frequency Identification) to improve inventory accuracy by 95%

- Artificial Intelligence identifies patterns and produces more accurate forecasts

- Analytics enhances logistics managers’ ability to plan operations, manage demand and improve processes for maximum efficiency

- Cloud Storage is the most secure and efficient method of storing data

- Immersive technologies such as Virtual Reality (VR) and Augmented Reality (AR) enable repair and maintenance capabilities in manufacturing, logistics and warehousing

Best practices for Supply Chain Management

- Improve inventory management with quick turns

- Recognize and remove the waste created by excess inventory

- Enhance collaboration with suppliers

- Maximize the yield for products

- Invest smartly in technology

- Provide security to investors and customers

- Retain customer relationships

Source:-https://www.camcode.com/asset-tags/supply-chain-management-guide/

Source:-https://www.procurementbulletin.com/understanding-the-3-levels-of-supply-chain-management/

Source:-https://brandalyzer.blog/2016/03/23/the-five-major-flows-in-supply-chain/

Source:-https://www.smartsheet.com/supply-chain-management

Source:-https://www.hollingsworthllc.com/infographic-7-technologies-supply-chains/

Source:-https://www.scmr.com/article/top_8_logistics_challenges_facing_the_industry

Source:-https://www.leandna.com/supply-chain-management/

Source:-https://www.sccgltd.com/archive/logistics-consultants-infographic/

Source:-https://www.ltdmgmt.com/logistics-best-practices.php